Tank temperatures begin to creep up during the summer months. A common misconception is that a mini refrigerator (affectionately known as a dorm fridge) can be used as an aquarium chiller. The purpose of this article is to explain why that is pretty much an urban myth that is repeated daily in the reefing DIY circles.

The Short Version

Mini refrigerators are only capable of moving a very small amount of heat per hour. The tiny compressors are not designed to run an extended duty cycle with warm refrigerant. Adding coils of tubing and buckets of water do absolutely nothing to increase the efficiency or capacity of a refrigerator and instead only (and poorly) time-shift the heat transfer. A dorm fridge may work ok on a nano tank or very small reef (30 gallons or less) that has only a very modest heat load. If you are inclined to trust what has been said here, then consider yourself informed. If you still have your doubts or the itch to learn, then please, read on and become informed! Become a DIY warrior in the constant fight against misinformation.

The Long Version

You will see many chillers and air conditioners rated in “Horsepower”. This is very misleading. The Horsepower rating only shows how much work the motor can do. That would be fine if we were trying to do work on, or add heat to, a given system. We are not doing work, we are moving heat! That is why we have ratings like EER (Energy Efficiency Rating).

Let me explain: Horsepower is meaningful if you are converting electricity into work or directly into heat. With an electric heater, the energy put in must equal the energy out. This is a basic law of physics. With a motor, the energy put in must equal the heat + the work put out, basic physical laws at work again. However, when you are cooling via phase change, you are not doing the opposite. Instead, you are transporting heat out of the system, not producing “cold”. So an air conditioner that uses 1000W of electricity produces 1000W of work+heat, however, it can move 5000W of heat out of your home! This is VERY important to understand.

Let me repeat that before we go any further! An air conditioner (chiller) MOVES more heat than it CREATES!

Let me repeat (again in different terms) that before we go any further! If a 1000W air conditioner is in the window (moving heat from the room and the heat that it, itself generates, to the outside) and a 1000W heater is in the same room (heating the room), the air conditioner will win, hands down. Don’t worry if you are still confused, I will show some examples to help make things clear.

Air conditioners and chillers commonly have their capacity rated in British Thermal Units (BTU). In general, a BTU is the amount of heat required to raise the temperature of one pound of water 1° Fahrenheit. Specifically, 1 BTU equals 1,055 joules. In heating and cooling terms, 1 “ton” equals 12,000 BTU (see inset for explanation of the logic). In the converse, to cool 1 pound of water 1° Fahrenheit, 1 BTU must be removed. Remember the rating of the unit refers to how much heat it can MOVE, not the amount of energy needed to move that heat.

What is “1 ton of ice”?

The latent heat of fusion for ice is 144 BTU/lb. This is simply the requirement for the phase change from liquid to solid. That is, to convert 1 pound of water at temperature of +32° Fahrenheit water into +32° Fahrenheit ice, it takes 144 BTUs. So if a ton is 2000 pounds, then to turn 1 ton of +32° Fahrenheit water into ice, it takes: 2000 lb x 144 BTU/lb = 288,000 BTU.

Refrigeration’s roots are in the ice making industry. Equipment manufacturers wanted a way to use the units in terms of ice production so that they could compare (sell) different units. If 288,000 BTU are required to make one ton of ice, divide this by 24 hours to get 12,000 BTU/Hr required to make one ton of ice in one day.

It is very important to understand that this has nothing to do with the amount of energy used by the system! We are only talking about the capacity of the system!

Now you know what a ton of air conditioning is.

The Energy Efficiency Rating (EER) of an air conditioner is its BTU rating over its wattage. For example, if a 10,000-BTU air conditioner consumes 1,200 watts, its EER is 8.3 (10,000 BTU/1,200 watts).

If 1 Watt = 3.412 BTU/hr, then the unit produces 4094.4 BTUs of heat (The motors, fans, friction, etc) that is absorbed by the air outside of the house but at the same time the unit moves 10,000 BTUs of heat from inside the house! Looked at another way: For every watt of energy that the AC unit consumes, it moves 8.3 watts worth of heat out of your home (or tank).

Now we have a basis for understanding some of the numbers and units that we will use to examine the dorm fridge chiller. From the above discussion it should also be very clear that buying a “1/5 HP” or “1/X HP” does not really tell you how much cooling capacity is available! The power rating just tells you how much energy the unit will suck out of the wall!

Notes On Compressors

The compressor is the heart of any refrigeration system. Compressors come in many sizes shapes and technologies, but they all have one thing in common; Their internal configuration dictates they way in which they must be operated.

Compressors come in three basic flavors, high, medium and low temperature. The temperature ratings refer to the expected suction gas (returning refrigerant) temperature in the motor case. Hermetically sealed compressors (the type used in refrigerators, chillers, A/C units etc.) are cooled by the actual refrigerant that flows through the system. The compressors motor windings are directly cooled by the suction gas that flows back from the evaporator. If the suction gas temperature is higher than the design specification for the compressors intended application, then the motor is subjected to much more heat than it was designed to handle. High motor temperatures significantly decrease the compressors life.

A refrigerator is designed to work under a very low heat load. Once the unit is cool, the compressor runs a very low duty cycle and the suction gas temperature is designed to be very low. Heat is removed from the interior of the refrigerator rather slowly. When the same compressor is subjected to high duty cycles and quick heat absorption from water, the motor windings are subjected to suction gas temperatures that are many times higher than the design specification. The same thing happens when you leave the refrigerators door open for several days. The motor will quickly give up the ghost under these conditions. Simply put, the compressor in a refrigerator or freezer is not at all suitable for use in an aquarium chiller.

An Air conditioner is designed to move large amounts of heat in a short period of time. The design parameters call for very high suction gas temperatures. The motor windings are made to withstand long duty cycles at high temperature. The design parameters make AC compressors much more suitable for use in aquarium chillers.

Mini refrigerators come in various sizes with compressors rated between 1/20 Horsepower and 1/8 Horsepower. As we noted above, the horsepower rating is pretty much meaningless and is only applicable if we care about the efficiency of the overall system, that is how many Joules of heat can be moved per Joule of energy consumed by the chiller. The average cooling capacity of a dorm fridge is somewhere around 150 BTU/hr, that is, it is capable of moving 150 BTUs of heat in 1 hour, regardless of how efficient (or inefficient) it is in terms of energy usage. For the purposes of comparison, a small window air conditioner can move 5,000-8,000 BTU/hr! If you step up to a mid size unit (the neck high models) they will be closer to 500 BTU/h.

Stop! That is not the whole story! The dorm fridge uses about 30% of its capacity just to keep the interior cool!

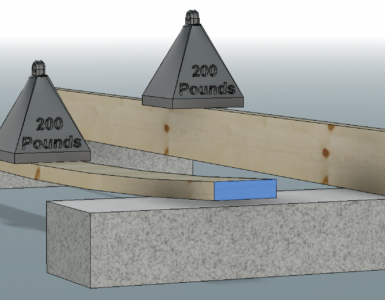

So lets put those numbers to work, shall we! We will take a target 75 Gallon system and model it with a decent 250 BTU/hr small refrigerator. Remember that 250 BTU/hr refrigerator will be able to devote about 175 BTU/hr to cooling the tank, the rest is wasted due to the design of the refrigerator!

If seawater weighs 8.5 pounds per gallon, then 75 gallons of seawater weighs 637 pounds. From what we learned above, we can say that it takes 637 BTUs of heat to change the tanks temperature by 1° Fahrenheit. It follows that our dorm fridge, working a 100% duty cycle (more on this later), can only drop the tanks temperature by .28° Fahrenheit per hour (or 1° Fahrenheit every 3.6 hours).

Lets expand on this example: Assume during the hottest 7 hours of the day, the tanks temperature rises from 80° Farenhiet to 87° Farenhiet without a chiller. We can translate this directly into BTUs! That is a 7° Fahrenheit temperature rise, or 4459 BTUs of heat that must be removed from the tank. Lets also assume that other 17 hours left in the day are cool enough for the tank to lose temperature on its own. Lets be kind and assume that the tank drops back down to 83° Fahrenheit by the start of the next hot period. Now lets model the dorm chiller on that same tank!

There is a LOT more that goes on here (the heat gain and loss are not directly linear, but the following is close enough for you to get the idea).

Lets look at a day in the life of the chiller and tank: It should also be noted that this example ignores the added heat by the chiller circulation pump and the extra heat load that the chiller adds to the room!

| HOUR | START TEMP | ROOM BTU | CHILLER BTU | NET BTU | END TEMP |

| 10 AM | 80.0 | 637.5 | -175 | 462.5 | 80.0 |

| 11 AM | 80.7 | 637.5 | -175 | 925.0 | 81.5 |

| 12 PM | 81.5 | 637.5 | -175 | 1387.5 | 82.2 |

| 1 PM | 82.2 | 637.5 | -175 | 1850.0 | 82.9 |

| 2 PM | 82.9 | 637.5 | -175 | 2312.5 | 83.6 |

| 3 PM | 83.6 | 637.5 | -175 | 2775.0 | 84.4 |

| 4 PM | 84.4 | 637.5 | -175 | 3237.5 | 85.1 |

| 5 PM | 85.1 | -112.5 | -175 | 2950.0 | 84.6 |

| 6 PM | 84.6 | -112.5 | -175 | 2662.5 | 84.2 |

| 7 PM | 84.2 | -112.5 | -175 | 2375.0 | 83.7 |

| 8 PM | 83.7 | -112.5 | -175 | 2087.5 | 83.3 |

| 9 PM | 83.3 | -112.5 | -175 | 1800.0 | 82.8 |

| 10 PM | 82.8 | -112.5 | -175 | 1512.5 | 82.4 |

| 11 PM | 82.4 | -112.5 | -175 | 1225.0 | 81.9 |

| 12 AM | 81.9 | -112.5 | -175 | 937.5 | 81.5 |

| 1 AM | 81.5 | -112.5 | -175 | 650.0 | 81.0 |

| 2 AM | 81.0 | -112.5 | -175 | 362.5 | 80.6 |

| 3 AM | 80.6 | -112.5 | -175 | 75.0 | 80.1 |

| 4 AM | 80.1 | -112.5 | -175 | -212.5 | 80.0 |

As you can see, not only does the dorm fridge run for almost 20 hours, but it can not keep the tank temperature from rising above a critical level!

It is time to talk about duty cycle! A refrigerators compressor is not designed to run nonstop. The motor and compressor are designed to run short duty cycles of an hour or so and kept cool by the refrigerant and oil inside of the system. Long duty cycles cause excessive heat buildup in this type of compressor and will shorten its life. If you have any doubts, leave the door to your mini-fridge open and you will find that the compressor burns up in a matter of a day or two!

If the dorm fridge is capable of moving 175 BTU/h then we do not want a heat load that exceeds 30%-50% of that. A suitable heat load for a dorm fridge chiller is somewhere in the neighborhood of 50-80 BTU/h depending on the unit. Smaller units may be closer to 30 BTU/h of acceptable heat load.

So what kind of tank are we talking about? Lets look at a 20 Gallon system that runs at 83 degrees without a chiller but has a target temperature of 80 degrees. The ΔT (Delta-T, or temperature change) is 3° Fahrenheit. Lets again assume that this 3° Farenhiet is gained over an 8 hour period if the tank has no chiller. 20 Gallons of seawater at 3° ΔT is 63.75 BTU/h. A MID SIZE refrigerator could be used here and would run about 50% of the time during the hot part of the day. The smaller dorm fridge will still be overtaxed due to an excessive duty cycle during the hot part of the day!

The efficiency of these systems is also very low. The systems are not charged to handle the large temperature swings, but instead are designed to keep the interior cold with an occasional small heat load (putting your warm six pack in to cool it down over a day or so).

As stated at the beginning of the article, the dorm fridges are suitable for no more than a nano or very modest heat load on a small tank. You will find many people who claim to have used such a DIY chiller on a larger tank. When the facts are looked at, it becomes obvious that the tanks heat load was nowhere near what was claimed! You simply can’t cheat the physics folks.

Alternatives

For those hell-bent on a DIY chiller, a cannibalized window shaker is ideal. The project will take a fair amount of skill and an extensive tool kit. For most people this means spending more time and money than the project is worth! See the projects pages for an upcoming DIY chiller build!

For those less brave, you may want to consider evaporative cooling! It is the most efficient way to cool a tank. You get over 8000 BTUs of cooling per gallon of water evaporated!

Great analysis, but I have a question: where are you getting the 150 to 175 BTU cooling capacity for a dorm fridge?

A typical mini-fridge may consume 50 to 80 W, so a unit might consume about 200 BTUs of energy. If the efficiency were only 2X, then it should be able to remove closer to 400 BTUs of heat per hour (granted that would require 100% duty cycle for that hour).

Your 150 BTU cooling capacity would put the fridge at closer to 0.7 efficiency???

Hi Greg – Thanks for asking.

There are several factors at play but I will try to be brief.

Firstly, the economy of scale for the small compressor/motor/ combinations is not good. They are simply not efficiently designed units compared to larger models.There are many technical reasons for this beyond the scope if this conversation.

Suffice to say that the “cooling” efficiency is going to be close to that 0.7 number or even worse for these tiny units. Also note that 80w of actual compressor is a fairly LARGE compressors for a typical “dorm” fridge. If the UNIT nameplate is 80w and it is is auto-defrost and most that nameplate wattage is leveraged during defrost, not cooling.

In any case you can take a look at actual compressor/motor nameplate ratings on these units and/or work backward from US energy efficiency requirements. Let’s quickly examine the later without doing a lot of math.

Per the department of energy technical documents. “Refrigerator compressor capacities range from as low as 125 Btu/hr (for compact refrigerators) to as high as 2,000 Btu/hr, although maximum capacities are more typically 950

Btu/hr for U.S. residential refrigerator-freezers.

The same technical document lists the following maximum efficiencies for “compact” refrigerators of various sizes

Watts, Btu/hr, CoP

117 400 1.38

103 350 1.26

59 200 1.04 <–this

41 140 0.76 <—or this is what we are dealing with

And these are best case maximums!

In any case the current 2022 guideline for compact refrigerators is 9.17AV + 259.3 and in 1998 the guideline for the compacts was 10.70AV + 299.0

I think we can safely skip the math here – The new standard has a slightly smaller kWh/yr multiplier but notice they bumped up the baseline a bit, meaning nothing has changed in these small units in 20+ years. They are cheap, not on the radar and extremely inefficient.

All of that said, simple proofs of these things can be done easily. Take a typical dorm fridge unit, plate a small lightbulb inside (say 10 Watts) and measure current consumption over a period if steady state temperature. You will be shocked at how poorly even your full size refrigerator in your kitchen performs with this simple experiment. All in, the average full size 26 cubic foot residential refrigerator will struggle to maintain steady state with even a modest 60W heat input.

-BeanAnimal